Week 15: Compliant and Flexible 3D Prints

As with everything in our world, 3D print material is able to bend when force is applied. We can use that to our advantage by designing 3D printed parts that are a single piece, yet flexible and “compliant”. You can even make 3D printed springs. This weeks project will highlight a few compliant 3D printed designs and have you design and print your own.

We will start with a simple design, a 3D printed spring. Follow along with the TinkerCAD video below. You are welcome to customize it to your own dimensions. Print this out and see how it works. Does it need any modifications? Should the spring walls be thicker or thinner and what does that change do? Would a spiral spring or circular design work better? Feel free to experiment!

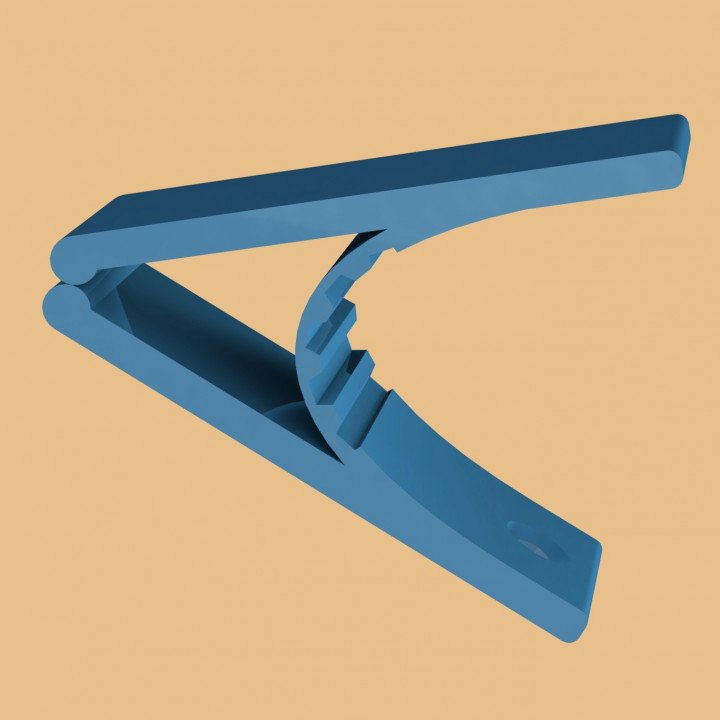

Now let’s design a pair of 3D printed compliant needle nose pliers. Follow along with the TinkerCAD video below. Feel free to modify the design however you like. Do the pliers need extra spring force to work? Would longer or shorter length tips work better? Does adding slits into the circular ring on the right make the spring work better? 3D print your first design then make modifications to make it better.

Check out these links for inspiration for more compliant 3D Printed mechanisms.

https://all3dp.com/2/compliant-mechanisms-3d-print/

Challenge Project:

Can you design a compliant rubber band shooter? Feel free to take inspiration from the internet or straight up copy the design shown below!